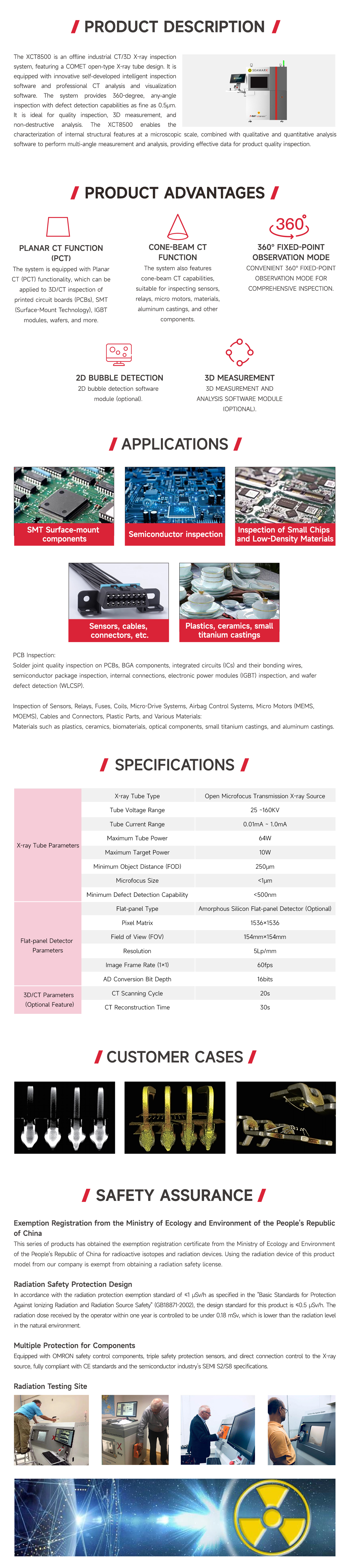

XCT8500 is an offline industrial CT/3D X-ray inspection equipment, designed with COMET open tube technology and equipped with innovative self-developed intelligent inspection software and professional CT analysis and visualization software. It has both planar CT and cone beam CT functions, and can inspect defects from any 360 degree angle with a minimum defect inspection capability of 1μm. It is suitable for quality inspection, 3D measurement, and non-destructive analysis. By combining qualitative and quantitative analysis software, the micro scale characteristics of the internal structure of the sample can be measured and analyzed from multiple angles, providing effective data for product quality inspection.

| 型号 | XCT8500 | |

|---|---|---|

| X-Ray Tube | X-Ray Tube Type | Open Microfocus Transmitted Ray Source |

| Tube Voltage Range | 20-160KV | |

| Tube Current Range | 0.01mA~1.0mA | |

| Maximum Tube Power | 64W | |

| Maximum Target Power | 15W | |

| Minimum Object Distance(FOD) | <300μm | |

| Micro Focus Size | 2μm | |

| Minimum Defect Inspection Capability | ≤1μm | |

| Flat Panel Detector | Flat Panel Type | Amorphous Silicon Flat Panel Detecor |

| Pixel Matrix | 1536x1536 | |

| Field of View | 154mmx154mm | |

| Resolution | 5.0Lp/mm | |

| Image Frame Rate(1x1) | 30fps | |

| AD Conversion Digits | 16bits | |

| 3D/CT Parameters(Optional Function) | CT Scanning Mode | Supports ACT and PCT Modes |

| 3D Visualization | Professional 3D Visualization Analysis Software | |

| Equipment Specifications | Maximum Sample Size | 645mmx635mm |

| Maximum Inspection Area | 500mmx500mm | |

| Image Geometric Magnification | 2500X | |

| Input Power | 220V 10A 50-60HZ | |

| Operation Syatem | DELL OptiPlex7000MT 12th Generation i9 Graphics Workstation(Workstation with Equivalent or Higher Performance) | |

| Dimensions | L1500mmxW1650mmxH2250mm | |

| Net Weight | Around 3210KG |